Learn about turning machining methods in mechanics

Similar to milling, turning machining is also being developed today, applied in cutting metal with workpieces to meet the needs of using products with accuracy, aesthetics and durability. high. Refer to the following article to better understand what turning is and the methods of turning turning in mechanics.

What is turning machining?

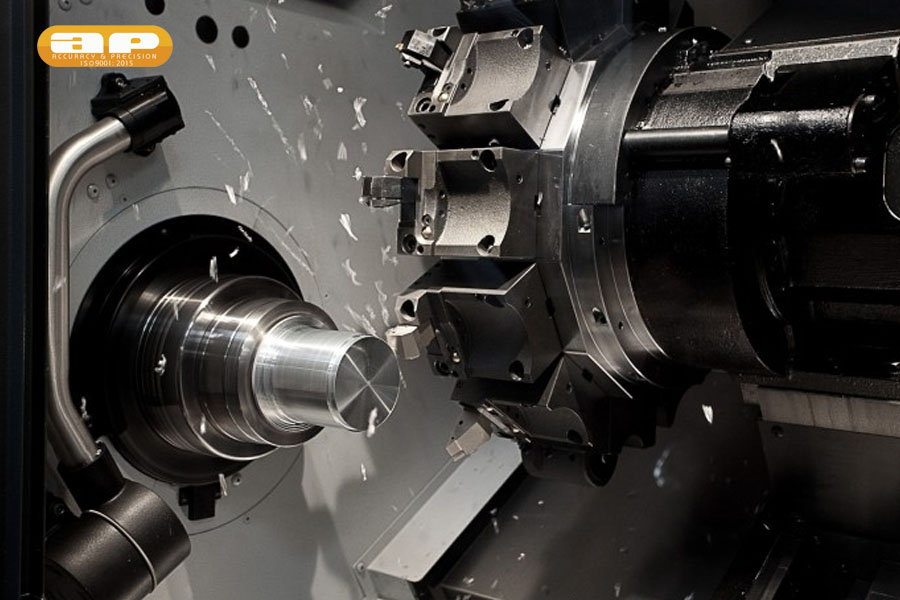

Turning machining is a material cutting method based on the circular motion of the workpiece and the reciprocating motion of the cutter (vertical or horizontal). If turning machining is done on CNC lathes, it is called CNC turning machining.

Previously, turning machining method was performed on mechanical lathes, operated by control of human. Since the development of technology, CNC lathes combine with an integrated automatic control system, making the turning machining process faster and more accurate.

The cutting tool used on a lathe is called a lathe. When processing on a CNC lathe, it will help to simplify all stages such as taper turning, bevel turning, round turning, face turning, slotting, …

Features of turning machining

- Turning machining is mainly performed for products. products with circular shapes such as conical, hole, eccentric, smooth shaft, …

- Diverse in lathe sizes, to meet all needs of product sizes for customers.

- Large capacity and high precision: When performing CNC turning to match the product size in high capacity conditions, the accuracy is still very high.

Current popular turning machining methods

The tool sizes are very diverse, soprocessing methods also have many different types for customers to choose from, specifically:

- Hole turning: This is a method of cutting the outer surface of the product. The method of creating holes of different sizes and diameters for products.

- Thread turning: This method only needs to use a basic turning tool to be used, so it is applied by many turning machining facilities.

- Oil face turning: The purpose of the method is to turn the surface of the product with many different types of turning tools such as straight-headed, flat-headed, curved-headed, etc.

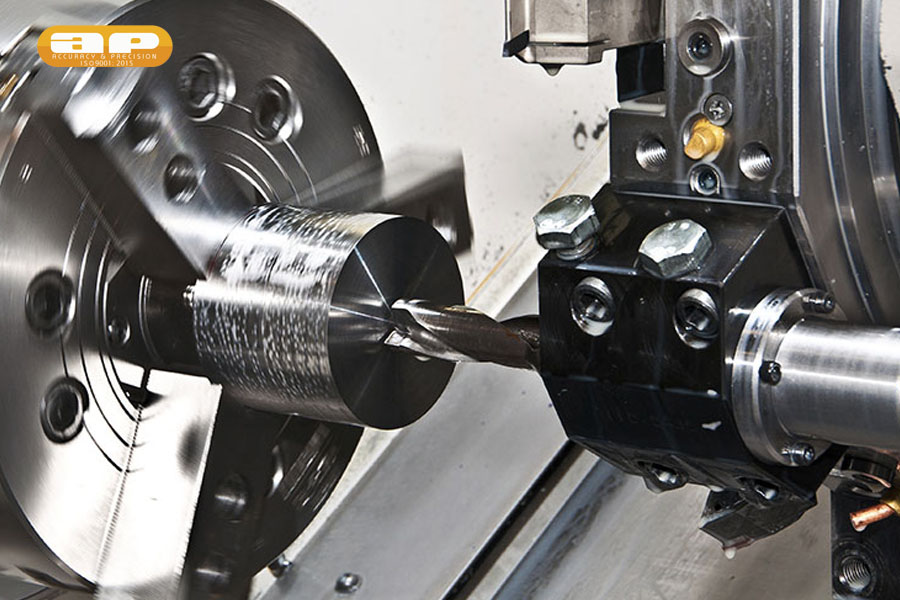

- Outer cylindrical turning: This is a machining method. The outer surface of the product with a turning tool produces cylindrical surfaces such as long cylindrical turning, horizontal cylindrical turning and wide finishing cylindrical turning.

- Cut-off turning: In the turning machining method, the cutting-turning method basically retains the same nature as the outer cylindrical turning, but the product turning requirements in this method are somewhat more stringent, the cutter also has the same durability. not tall.

Advantages of CNC turning method

- Use suitable turning machining method when machining parts with round shape.

- The operating modes of the lathe are quite simple and easy to implement.

- CNC lathes have high applicability, in addition to lathe processing, they can also be used in boring, drilling, grinding, grinding, chamfering,…

- High-precision CNC turning machining method creates products. quality products.

Disadvantages of CNC lathe method

- Accuracy of lathe method affects turning tools, workmanship, processing materials,… For each type of material, it is necessary to choose the appropriate type of tool and cutting mode. Turning processing

- Method depends heavily on the shape of the part, therefore. For products with more complexity, the milling method will be selected.

Standard CNC turning machining process

The following are the basic steps of CNC turning machining for your reference:

Step 1: Check the workpiece against the drawing and check the machining material

Measure the workpiece size compared to the size size on the drawing, check the workpiece material.

Step 2: Rough turning machining the workpiece

Based on the exact dimensions of the part on the drawing and the size measured on the workpiece, then the workpiece will be roughed.

Step 3: Check design data

Check on detailed drawings such as: shape, size, roughness, processing materials.

Step 4: Programming CAM

CAM is the successor of computer-aided engineering and is often used in tandem with computer-aided design.

Check the CAM program

Step 5: Install the CNC lathe

- Check the part machining dimensions

- Eliminate unnecessary programs

- Install the tool

- Set the X-direction so that the center of the chuck coincides with the drill bit

- Adjust the tool length

- Mount the tool and jigs on the chuck

Step 6: Operate the CNC lathe

- Operate the part machining machine

- Measure and evaluate the required dimensions

Apro machining CNC turning on demand quickly Turning

method is considered an effective method in metal cutting and is widely used in the field of metalworking. mechanical processing sector. There are many types of lathes with different sizes, so the product is also very diverse.

Apro is one of the units that receive turning machining processing with many different methods to meet all your requirements. With modern machinery and equipment, precision mechanical products always ensure quality, fast processing time with the best price.

For more information, please contact Hotline: +84 774 168 999 for advice from support staff.