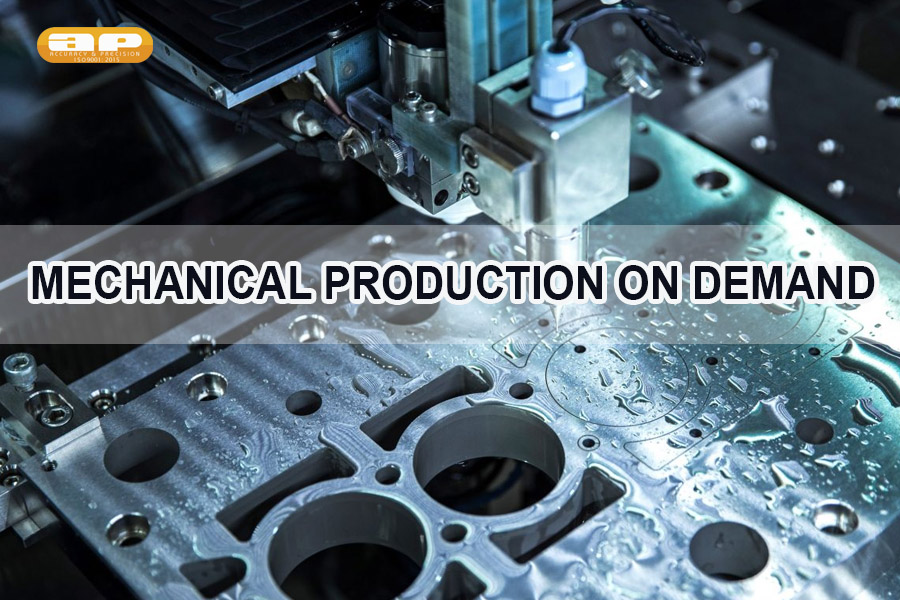

Prestigious and cheap mechanical factory on demand

Mechanical production on request is a service of interest and plays an important role in the development of industrial production. Therefore, there are many mechanical processing companies, but choosing a reputable unit is not easy. In particular, Apro is proud to be a unit with many years of experience, committed to providing a

mechanical production on request accurately and quickly.

Learn about the mechanical production on request

Mechanical production on request is the industry that creates products, equipment, accessories, machine parts, … Serving for the production, assembling of machines and many other economic activities.

This is an extremely important industry contributing to accelerating the process of industrialization and modernization of the country.

Technology used in mechanical production on request

- Workpiece processing technology: the support of machines, but needs milling, turning, cutting, planing, grinding, … of the mechanic.

- Non-workpiece processing technology: deformation or hot working to create mechanical products by forging, pressing, casting, drawing, stamping, welding,…

- Other processing technology: wave machining ultrasonic, electrical spark processing…

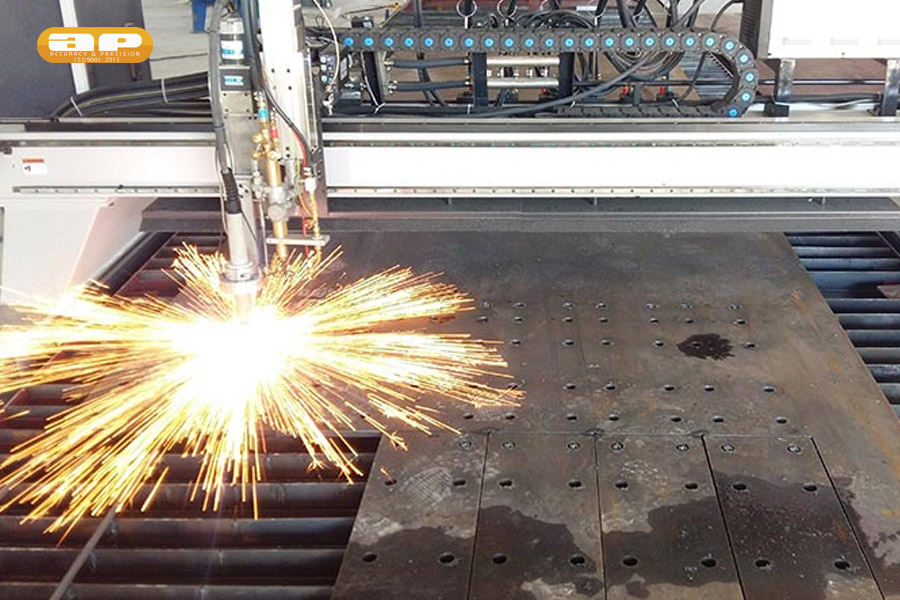

Some forms of mechanical processing

Mechanical production on request is divided into two forms: precision mechanical processing and mechanical processing.

- Precision mechanical machining: this is a machining method with a laser cutting machine controlled by cnc software (laser cutting machine according to pre-designed drawings). Combined with a highly qualified mechanic will create extremely high-precision products in the right shape and according to the drawings.

- Machining: the processing method requires the hands of a mechanic, through operations such as milling, turning, grinding, cutting, … to create products as required.

Large mechanical workshops receive mechanical production on request in accordance with samples and drawings, with high complexity. Small mechanical workshops only accept mechanical processing.

Apro materials receive mechanical production on request

Apro owns a variety of modern machines and equipment ready to meet all the needs of mechanical processing, processing different materials at the request of customers. client. Specifically:

Metal material processing on demand

Apro receives metal mechanical processing is divided into 2 main groups:

👉 Ordinary metal:

- Mechanical processing of cast iron: ductile iron, spherical cast iron, gray cast iron, white cast iron ,…

- Mechanical processing of steel: SUS420, SUS430, SUS440, SUS304, SKD11, SKD61,…

- Mechanical processing of stainless steel: SUS304, SUS304H, SUS304L, SUS201, SUS430, SUS316

👉 Non-ferrous metal:

- Mechanical processing Aluminum gas: A6062, A7075, A5052…

- Mechanical processing of Nickel and Permalloy alloy.

- Tin mechanical processing.

- Mechanical processing Copper: red copper, copper alloys including LaTong (LCuZn30, LcuZn20Pb1…), Brong (Aluminum brood, Tin bronze, Lead bronze).

In addition, Apro also accepts to process a lot of other materials on request to ensure the best meet the needs of customers.

Mechanical processing of non-metallic materials on request

Besides metal materials and alloys, Apro also accepts mechanical production on request with non-metallic materials such as:

- Rubber: Synthetic rubber, heat-resistant rubber, EPDM rubber…

- Plastic: including thermoplastic PE, PP , PVC, PS, PC, ABS, PA… and thermosetting epoxy (EP) and Phenol (PF)

- Wood: Woods according to customer’s requirements.

Criteria to choose a mechanical manufacturing unit according to the prestigious requirements

Currently, the number of units operating in the field of mechanical production is increasing. To choose a reputable and professional mechanical factory. The following are the reasons that you should choose Apro for mechanical production on request, specifically:

Modern mechanical production machinery system, advanced processing technology

To bring mechanical products that meet With high quality and aesthetics, the equipment with modern electrical machinery and advanced processing technology is indispensable.

When you choose a mechanical workshop, you should ask your partner to provide a capacity profile to see the modern machinery system firsthand. Is it possible to meet the product processing requirements as required or not?

High-precision mechanical workshop

If products have low precision, scale, and dimensions are deviated from the original drawings, their application is also low, leading to serious losses. Choosing a mechanical processing unit is extremely important.

When processing machine parts, cnc punching, mechanical products for industries that require almost absolute precision.

Ensure fast processing

progress Ensure the correct construction schedule does not affect your work plan. This is clearly stated in the contract, the manufacturer will be responsible if the production schedule is not guaranteed.

Competitive cost

Apro receives mechanical processing at a low cost, reasonable with your needs, ensuring competitive prices compared to the general market, ensuring optimal costs for customers.

For an exact quote, contact us Hotline: +84 774 168 999

A team of highly skilled engineers and mechanics Mechanical

processing has the support of modern machines, but the human factor is still the key determinant of quality and durability. of mechanical products.

Apro always has a team of experienced and highly skilled workers in the field of precision mechanical processing.

Outstanding advantages of precision mechanical production

- Saving machining time: With modern machines and equipment, it is possible to process any metal into a desired product part without spending too much time like simple machining methods.

- Increase product quality: The parts have high precision in size, the smoothness of the product surface is much better than other simple machining methods.

- There is no high requirement for processing materials, as all materials can be precisely processed even with high complexity.

- With modern equipment and machines, you can create any mechanical product and machine detail exactly according to your requirements.

Reasons to choose mechanical processing workshop Apro

Apro has experienced many years of experience in mechanical production. We are trusted by many customers because of our reputation and professionalism in the market today.

Apro provides mechanical products nationwide, products are diverse in size, different models:

- CNC bending, black steel, stainless steel, aluminum, copper, … multi-shape

- CNC punching, hydraulic punching

- Laser cutting sheet metal steel, stainless steel, aluminum, copper, pipes, boxes of all kinds

- CNC grooving black steel, stainless steel, aluminum grooves, copper grooves

- Machining mechanical products for the construction industry

- Machining mechanical products for the domestic industry Exterior

- Machining and finishing products

- Machining mechanical products for the supporting industry

- Outsourcing mechanical products for the advertising industry

With a team of highly qualified engineers and skilled workers, Apro would like to Commitment:

- Mechanical production on request to customer requirements with the highest accuracy and best durability

- Ensure processing progress, product delivery according to plan

- Optimize processing costs to save maximumyou

Have a need for precision mechanical processing, please contact Apro immediately via Hotline: +84 774 168 999 for advice on mechanical production on request. uponcredit – professional – cheap – quality.