Commonly used CNC milling methods

Currently, CNC milling is a very popular machining method in the mechanical manufacturing industry. This method has high accuracy but also automates the production process. As a result, the production process is shortened, saving time and costs.

CNC milling is applied in aerospace, marine, machinery manufacturing industries,…

What is CNC milling method?

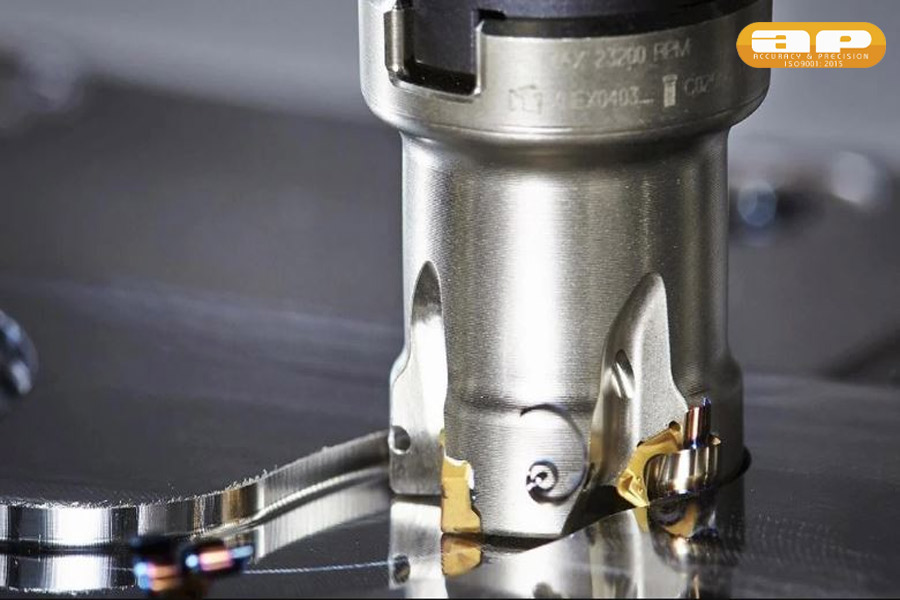

CNC milling is a machining method that cuts on raw materials, also known as workpieces. CNC milling machines are controlled automatically through computer programming.

When processing, the workpiece will be clamped to the fixture on the CNC milling machine table. The tool stored in the spindle will move to the workpiece and proceed to remove excess material to create products with the desired shape.

The benefits of CNC milling machines include:

- Automating production processes, shortening machining time and saving costs,

- helping to ensure uniform accuracy between programmed products By computer, the products are uniform, avoiding errors.

- CNC milling machines can process materials such as iron, zinc, aluminum, etc.

- Because it is a high-tech machine, it can produce high-quality products. large products in a short time, while still ensuring high performance.

- CNC milling technology is used in many industries such as: marine, automotive, aerospace,…

Popular CNC milling methods Today

There are the most popular CNC milling methods such as:

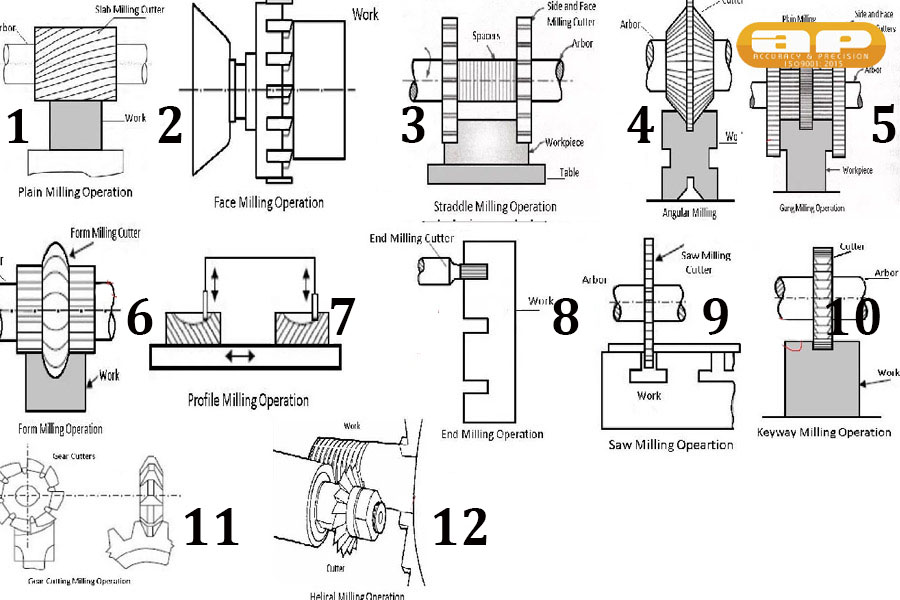

Plain Milling

This is a surface milling or sheet milling method. In this smooth milling method, the cutting tools rotate parallel to the surface of the workpiece to produce flat surfaces.

Face Milling

This is a milling operation where the cutting axes rotate around the axis of rotation, perpendicular to the workpiece surface. The face milling method is the simplest milling method. This method is often used to create flat surfaces and contours on workpieces to be machined.

Side Milling

This is a milling method with a side milling cutter to create a vertical plane, slots, and grooves of the workpiece.

Belt Milling

This is a method of creating a vertical flat surface on both sides of the workpiece by using 2 face milling cutters. Square or hexagonal surfaces often use belt milling for machining.

Angle milling method

This is a method of creating an angular surface on the workpiece. The cutting tool of this method has the axis of rotation at an angle to the workpiece surface.

Pattern Milling

This is a method of creating contours with unequal cutting angles using a pattern cutter. The surface of the product after machining will be checked with a ruler.

Profile Milling

This is a milling operation with a milling cutter for finishing straight or inclined surfaces.

Saw Milling

This is a method of creating narrow slots or grooves in a workpiece by using a saw tool.

Slot and Slot Milling

This is the operation of creating grooves and slots of different shapes and sizes. This method can be done by disc milling cutters, end mills, etc.

Gear milling

This is a milling method to produce gears. The workpiece is mounted perpendicular to the axis of the cutting tools. knife will move along the length of the tooth to create the gear. After each of these, the cutter is withdrawn and another tooth is cut. This process is continued until the gear is perfected.

CNC milling process according to modern technology

This process includes the following steps:

Step 1: Design the CAD model on the computer.

Simulate the shape of the product to be manufactured on the computer through the CAD model available on the computer.

Step 2: Proceed to convert the CAD file into a CNC milling

program This process will control the machine operations and the movements of the tool on the workpiece, ensuring that the product is machined exactly according to the programmed commands. .

Step 3: Proceed to prepare the CNC milling machine

- Perform size check and place the workpiece on the table of the CNC milling machine

- Determine the 2D, 3D standards

- Install the appropriate cutting tools into the tool store

- Proceed Adjust the machine parameters back to 0

- The milling program is pre-programmed and downloaded

Step 4: Start performing the CNC milling process

Modern CNC milling machines will automatically operate on the prepared workpiece according to the instructions of the prepared program.

Step 5: Monitoring the operation of CNC milling

When the CNC milling machine is in operation, it is advisable to avoid manual intervention in the operation of the machine, but to monitor them.

APRO Precision Machining Co., Ltd accepts CNC milling according to customer requirements

Our company always providesservice package CNC milling according to the requirements of customers. With a staff of experienced and enthusiastic customer care, we are committed to providing customers with beautiful and unique designs, products that are consistent with the design and uniform.

When customers use our CNC milling service, with large orders, the price will be reduced.

Any need to buy, use services or design and manufacture consulting, customers can contact us directly via hotline 0774168999 to be consulted and answered by our staff. infected.

Above is all information about CNC milling at the request of customers. Hopefully, the information about the methods and structure of CNC machines will help customers have the right view of CNC milling in the mechanical manufacturing industry.