What is mechanical part manufacturing? The role and process of mechanical production

Detailed mechanical production plays an important role in the industry in Vietnam. Along with increasingly modern technology, the mechanical processing production process is increasingly developed. But the production of detailed mechanical production needs to have a specific and fast process to ensure the most accurate product quality. Apro will share with you the detailed mechanical production information below the following article.

What is detailed mechanical production?

Detailed mechanical production is the use of modern machinery, techniques, technology and raw materials to create high-precision mechanical products to serve the needs of people’s lives. .

Mechanical engineering applies the principles of physics, materials science, engineering science, and modern techniques in the production of mechanical parts. The products are created and applied to economic activities such as manufacturing machinery and equipment for the construction and construction process,…

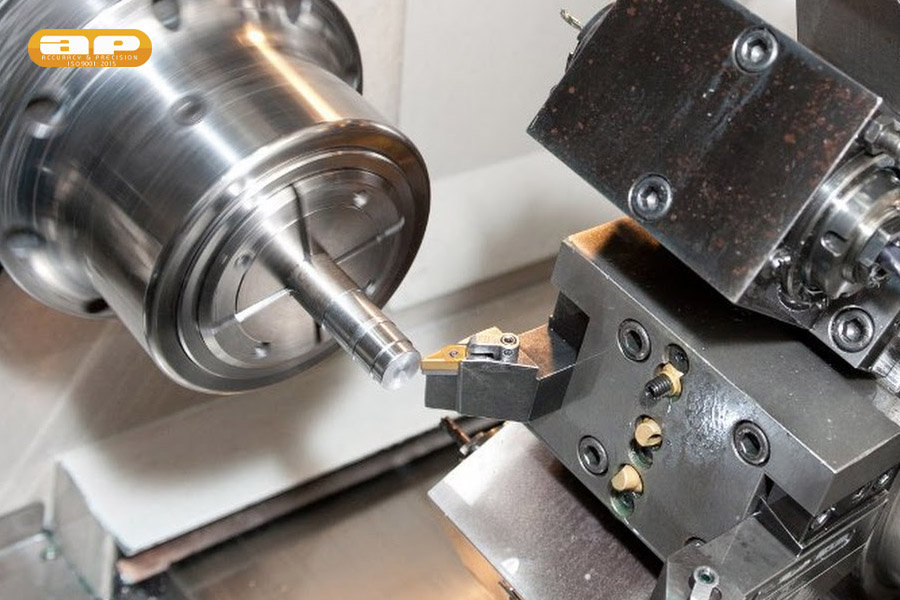

The mechanical industry has made many outstanding advances thanks to the advancement of technology. science Technology. Some types of specialized machines used in mechanical production are laser cutting machines or CNC cutting machines. These types of machines help to form products with high aesthetics, good quality and saving effort.

Currently, the production of mechanical parts is usually done by cnc machines. With advanced cnc technology, all machining operations are performed automatically without human intervention. Ensure product accuracy and quick construction time.

Some common concepts today

Product

This is a conventional noun for material. product created at the final stage of a mechanical part manufacturing process.

Machine Detail

The smallest and complete unit of the machine. The characteristic of the machine part is that it cannot be separated and has met all the necessary specifications.

Machine parts have two types:

- Parts with general use: These are parts that can be used in many different machines. For example: bolts, nuts, gears, etc.

- Specific machine details: These are the parts that are only available in a certain machine. For example: crankshaft, camshaft, etc.

Machine structure

Is a part of a machine or a machine part that has a certain task.

For example: chain drive, belt drive, etc.

Machine part

This is a part of the machine. Consists of two or more machine parts linked together according to certain machine principles. A machine, a device is composed of many machine parts.

Billet

is a conventional technical noun that refers to a block of raw materials, the main material being processed to create the final product of the manufacturing and mechanical processing process.

Ingots include the following types:

- Castings (Products of casting production).

- Forging billet (Product of forging production).

- Stamping billet (Product of forging production).

- Rolling billet (Product of rolling production).

- Welding workpiece (Product of welding production).

What is the role of detailed mechanical production?

Manufacturing, manufacturing and precision mechanical processing is one of the important fields, playing a great role in influencing the development of the economy.

- Mechanical processing using modern machines and equipment is gradually replacing manual labor, making everyone’s working process lighter and more productive.

- Thanks to applications in the mechanical industry, people’s vision is expanded, capacity is enhanced.

- The mechanical industry is the key to all countries, the basis and foundation for the development of a modernized country like Vietnam.

Essential elements in the production of detailed mechanical production

Types of materials Materials used in the production of mechanical parts include: stainless steel, iron, steel, aluminum…

Necessary machinery used in the production process: mechanical processing by laser, mechanical processing by CNC machines. The use of these machines helps to make the production process faster, save labor and materials of the processor and increase the accuracy, sharpness and shine of the finished product.

Technology applied in the manufacturing process:

- Workpieceless machining technology: is a processing technology based on pressure and hot working, including operations such as cold stamping, casting, hot stamping, welding, forging, rolling, pressing , scissors…

- Workpiece processing technology: includes turning, milling, grinding, cutting, and planing activities.

- In addition, there are a number of other technologies used in the manufacturing process of a mechanical product such as machining. ultrasonic waves, electron beam machining, spark machining.

Professional detailed mechanical production process

It is necessary to have a complex production process to create good quality products with the required shape and size. Detailed mechanical production is a human impact through production tools including many different stages. Specifically:

Step 1: Design drawings for products

The first thing to create perfect machine parts, you need to study the details of the drawings, learn carefully the functions of each part and analyze them. type them. In particular, when designing drawings, it is necessary to meet the necessary technical requirements as well as meet modern technologies at each time.

Step 2: Determining the right production form

There are 3 main types of production:

- Single-piece

- production Mass

- production Mass production

Step 3: Workpiece selection and billet manufacturing method

Want to make a successful machine part With technical requirements and economic criteria, the technological process must select the method of manufacturing the workpiece and determine the appropriate size of the workpiece.

Step 4: Plan production and implementation steps

Before creating the machine parts, you need to carefully review the step-by-step process to ensure the finished product is of high quality in the shortest time possible. body.

Step 5: Selecting equipment for work

The job of selecting equipment and tools has an impact. quality, productivity as well as processing cost. Therefore, when designing the mechanical production process, it is necessary to carefully analyze when choosing the right equipment and tools.

Step 6: Determine the amount of residual processing

After completing the technological steps to process the equipment, you should compare the options to choose the most optimal one in each machining condition. Depending on the implementation method, each production process will use its own documents and production instructions.

Step 7: Check the quality and hand over to the customer

After performing the mechanical production processes of machine parts and choosing the right process, we will start implementing and have the products. associated with each process.

Finished products need to be thoroughly tested before being marketed and put into operation to ensure that subsequent problems are not caused by the supplier’s fault.

What is the most prestigious and professional mechanical detail manufacturing unit

When learning about manufacturing mechanical parts? You already understand that creating a quality mechanical product is not simple and easy. It is a complex machining process. Must depend on modern machinery and equipment, especially skillful hands and efforts of mechanics.

At Apro the manufacturing processes of mechanical parts have been standardized. Ensure the best product processing quality, supervised by experienced experts in the field. Customers feel secure when using our services.

For consulting support and service quotes, please contact us via Hotline: +84 774 168 999