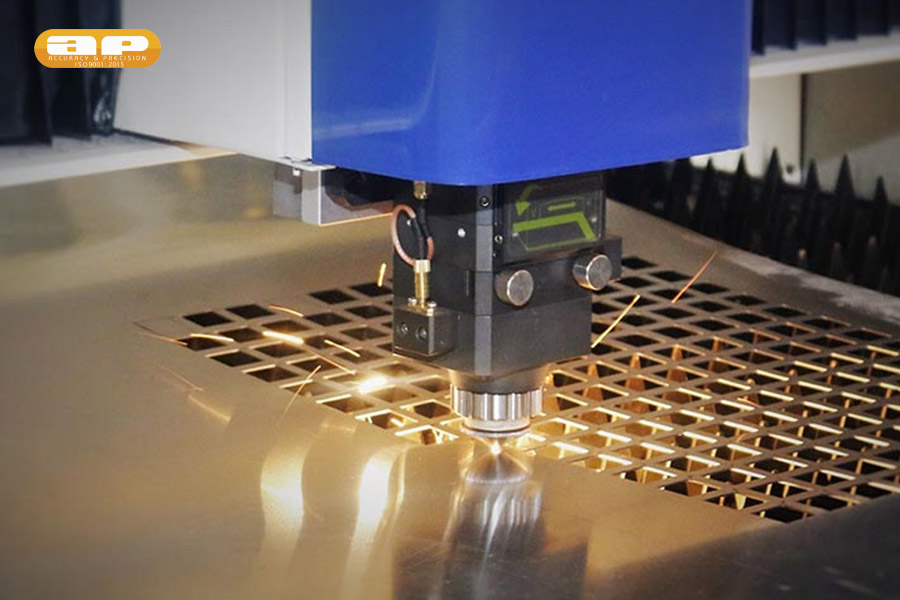

Processing method of hot stamping components

The processing method of hot stamping components is commonly used in mechanical processing today. This toolkit is capable of machining on a wide variety of materials. This technology often has to operate in a high temperature environment with continuous time, so the hot stamping die has good heat resistance and bearing capacity. Let’s learn more about the hot stamping mold set below the following article.

Learn about hot stamping die

This is the part used to process lower hot stamping parts. the effect of stamping force to shape the product as required. The material billet will be heated at a high temperature to make it easier to process hot stamping components. However, this temperature level needs to be adjusted appropriately to ensure the deformation factor in the manufacturing process.

The most commonly used hot stamping die technology. As for cold stamping dies, products that are too hard or have high complexity cannot be processed. Force factor and product quality are not guaranteed. With hot stamping dies, this method can be used with thick, high hardness metal sheets. Under the effect of heat, the sheet metal will become more malleable and soft. Enterprises will easily process hot stamping components on the surface of the product.

Common hot stamping parts processing

method Hot stamping parts processing method is a method of manufacturing metal products under the action of stamping force. The performance condition for this method is that the metal is heated to a suitable temperature. Unlike cold stamping, hot stamping is capable of creating many products with high complexity. Enterprises can create many products in one stamping cycle. This technology helps to improve labor productivity significantly.

Using hot stamping parts processing method, hot stamping die is an indispensable part. With this type of mold, it is necessary to have good heat resistance and bearing capacity. Mold selection plays an important role in determining the performance and quality of the product. after machining.

Structure of hot stamping die The

structure of hot stamping die consists of 2 components: mold shell and mold core. In which, the mold cavity will be divided into 3 types: rough stamping cavity, fine stamping, and prepared mold cavity. In order for the mold cavity to have the best quality, it is necessary to pay attention to the following 3 factors: angular radius, slope, burr groove.

With mold shell, it is made of steel material with good bearing capacity and heat resistance. During the production process, the mold shell will not be deformed to ensure the quality of the components when machining.

Required technical requirements of hot stamping die

- system has high gloss and smoothness to ensure product quality

- The tolerance ratio of the mold cavity must be kept to the minimum

- Mold material has the hardness and ability Good heat resistance

- The entire processing of hot stamping components needs to be done by experienced staff in the field

- . Technical safety factors for users should be ensured

- Design drawings should show details. details of each part and parameters of hot stamping die

Advantages and disadvantages of hot stamping dies

Advantages The

- after being processed are guaranteed for high accuracy

- Hot stamping dies with high mechanical strength

- Able to process over many products require high complexity

- Can be combined with modern production line system

- Significantly improve labor productivity

Disadvantages

- Low mold strength due to continuous operation in high temperature environment

- Workpiecepre-forged by hand

- The cost of making the mold is high

- With products at room temperature, it won’t work p for this method

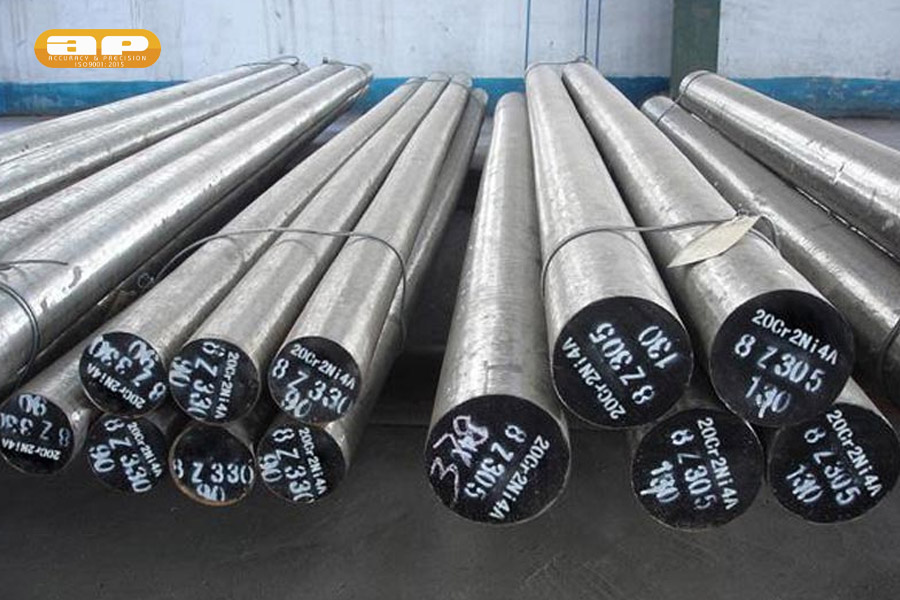

What material is the hot stamping die made of?

Hot stamping dies usually operate in a continuous high temperature environment. Therefore, the mold is made from steel that has good bearing capacity, good heat resistance and is not deformed during the processing of hot stamping components. Several types are commonly used for this technology:

- DAC steel: This steel has good strength and ductility, it has high heat resistance. The hardness of the DAC is about 48 HRC. Therefore, it has good machinability and little deformation after heat treatment.

- FDAC Steel: The hardness of this steel is 38-42 HRC, it will provide a large amount of sulfur making the machining process easier.

- SKT4 steel: With this steel, it is commonly used in the field of hot stamping and casting molds.

- DAC-MAGIC steel: This steel has high machinability and good resistance to thermal cracking. The hardness of DAC-MAGIC will range from 45-52 HRC.

Cheap hot stamping parts processing company – quality

Apro is oneunits hot stamping components processing most prestigiousWe are capable of processing many different types of components by hot stamping. Therefore, with any product that customers can contact to process at Apro.

When using our service, you will be supported with advice on component processing. Production costs are effectively used for each item and in accordance with the needs of customers. The company also has long-term warranty policies for hot stamping components processing services. Customers can use the company’s services with complete peace of mind.

Please contact ☎️ +84 774 168 999 for support and advice.