Manufacturing custom molds at Apro

Mechanical processing must require high accuracy and no deviation, the tolerance index for mechanical products is always at the lowest level. Especially with the production of molds for processing components, more attention must be paid to accuracy. Therefore, the quality requirements for mold production are increasing.companies mold manufacturing with a team of experienced engineers. Let’s learn more about the mold making process in the following article.

What is pattern learning?

A mold is a tool (equipment) made of metal used to shape products according to the shaping method. Each mold is made and used once or many times to create the finished product. The structure and size of the jig depends on the size, shape, quality and quantity of the product to be created.

Molds are made based on existing products, the mold processing process is the production of product molds according to customer requirements, mass production of the same products and the same sample as guaranteed. function and use, without losing the effectiveness of the product.

Professional custom mold manufacturing process Custom jig

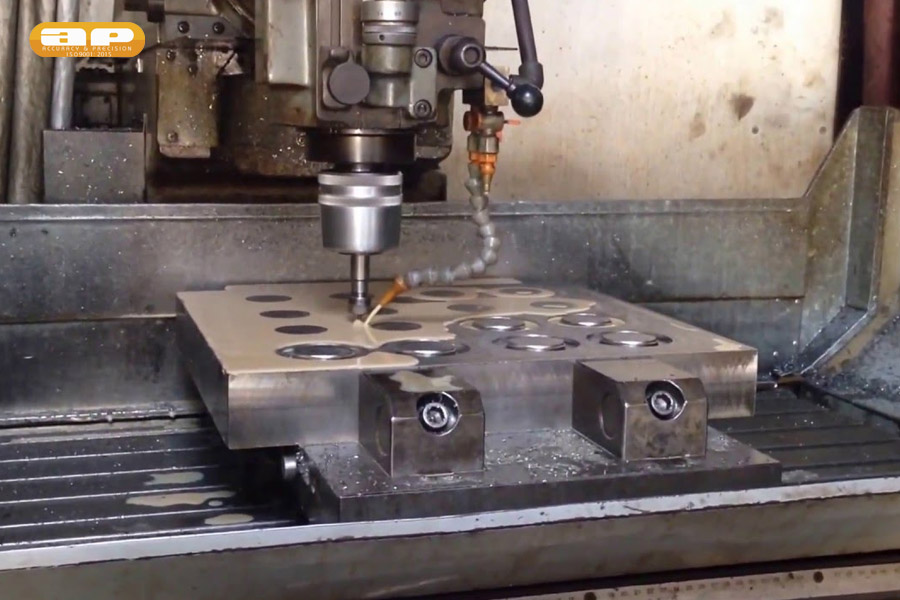

Production requires must meet customer requirements. Apro is invested in new CNC machining equipment and machine tools to make mold production as required.

The following is the mold manufacturing process according to the following specific steps:

Step 1: Receive information about customer’s mold making needs.

Step 2: Get standard details, mold products and plan production. Then will create a sample and test.

Step 3: Design and create mold manufacturing data on CAD/CAM/CNC.

Step 4: Process the surface, parts with simple shapes by 2D shaping machining methods.

Step 5: Assemble the mold plate together into blocks.

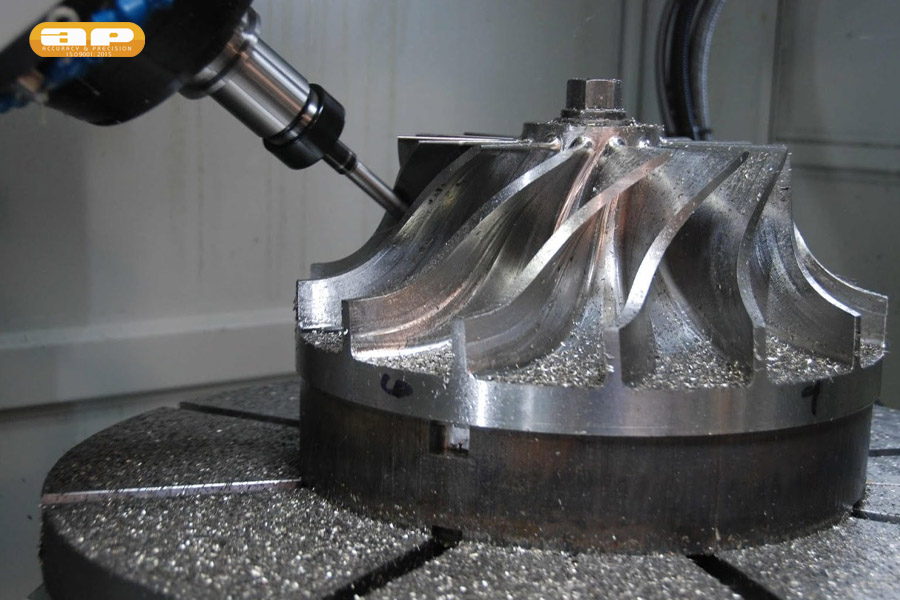

Step 6: Machining complex surfaces by 3D forming machining.

Step 7: Polish the jig detail. Mold inspection and testing.

Step 8: Finishing the mold, making supporting parts for mold transportation.

Step 9: Close the package and deliver the mold to the customer.

Step 10: The customer checks and accepts the product.

Types of popular

Molds these types of jigs are widely used in mechanical engineering to create parts from various materials such as metal, rubber, plastic, glass and other inorganic substances. Products from injection mold include metal parts in household appliances, electrical appliances, consumer goods, military equipment, medical products, in cars, airplanes,…

Molds used in Plastic products manufacturing includes several types as follows:

- Compression

- Mold Reinforcement

- Mold Injection Molding

- Mold Blow

- Mold Extrusion

- Mold Rotary

- Mold Die Casting Mold The

Most common of which is injection molding.

Stamping dies are used to manufacture a wide variety of metal products, using a variety of methods such as extrusion, hammering, forging, drawing. Stamping products are used in the manufacture of aircraft, automobiles, furniture, industrial machines, household products, construction equipment, electronic equipment and many other products.

Applying technology to manufacturing jigsaw

Mold manufacturing in an ever-growing industry develop. With the ability to create products in large quantities, short production times, and high stability, maxi mold products are indispensable in the industrial manufacturing industry, from household products to consumer products. air and modern electronics.

Technologies used in the production of jigsaw molds are typical mechanical technologies and properties. The mold manufacturing industry technology can be used as a basis for scaling up the entire mechanical industry easily.

New technology in manufacturing plastic molds and molds Plastic mold

Making with new technology in plastic mold making plays an extremely important role in the development of the mold industry.

Making plastic molds by CAD application CAD

Design software is widely used in many fields. This software specializes in designing and creating product models in the form of 2D or 3D drawings, simulation drawings with perfect realism close to the real product after completion.

Plastic molds with high complexity will be simplified through the perspective of CAD software, ensuring accuracy and speed.

Applying CAM to plastic mold manufacturing

Similar to CAD, CAM is mechanical processing software installed on a computer. However, the CAM is not used to create designs but is like an operating system that is the main set of devices and machines through a computer.

CAM has the function of analyzing data, calculating parameters given from detailed CAD and then controlling CNC machines to operate. Using CAM technology makes automation machines work according to preset programs. The technician will monitor and order the operating program of the machine.

The plastic mold product is successfully manufactured and the tolerance of each mold is limited to the maximum.

Plastic mold processing by CNC

Application CNC application is a high-tech machine with almost absolute accuracy. CNC machines include: lathes, milling machines, cutting machines, laser punches,…

CNC machinery systems operate automatically through the programming of CAM software. Product quality meets world leading standards. Large plastic molds or small plastic molds, CNC machines can produce high-precision products.

The CAD/CAM/CNC mold manufacturing technology is the most modern software, equipment and machinery. Existing into a system, a complete and unified operating process follows a certain process.

Laser mold

Engraving technology Laser mold engraving technology offers many advantages. important in the tool and mold manufacturing industry. Capable of non-contact material handling, high beam concentration for durable etching. Non-contact processing reduces the risk of mold damage and deformation. Laser technology always ensures high accuracy and repeatability of engraving with the following advantages:

- Engraving at an extremely fast speed of 1500mm/s – 30 times more than the previous method.

- Can engrave on hard-to-reach work areas and concave/convex workpieces with high precision.

- Environmentally safe because the laser does not produce harmful substances like the axis engraving method.

Custom mold production service at Apro

Apro receives mold production according to customer requirements quickly. With modern equipment and machinery to create quality products, short production time and high stability. CAD/CAM/CNC technology is modern machine software with absolute precision, unified and complete operation. Apro has a team of experienced and skilled engineers in the field to ensure the best quality products.

If you have a need to manufacture molds , please contact Apro immediately via Hotline: +84 774 168 999 for advice and quotes on mold processing.