CNC cutting on demand – professional – prestigious

Apro company specializes in CNC cutting on demand with modern technology, quality products, competitive prices, door-to-door delivery. Let’s learn about the CNC cutting on demand below.

Learn about CNC cutting

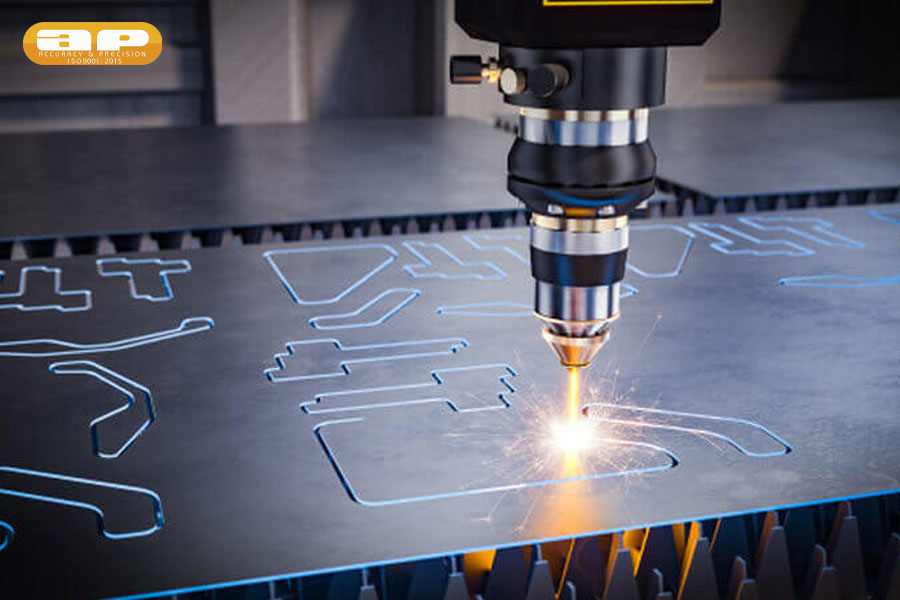

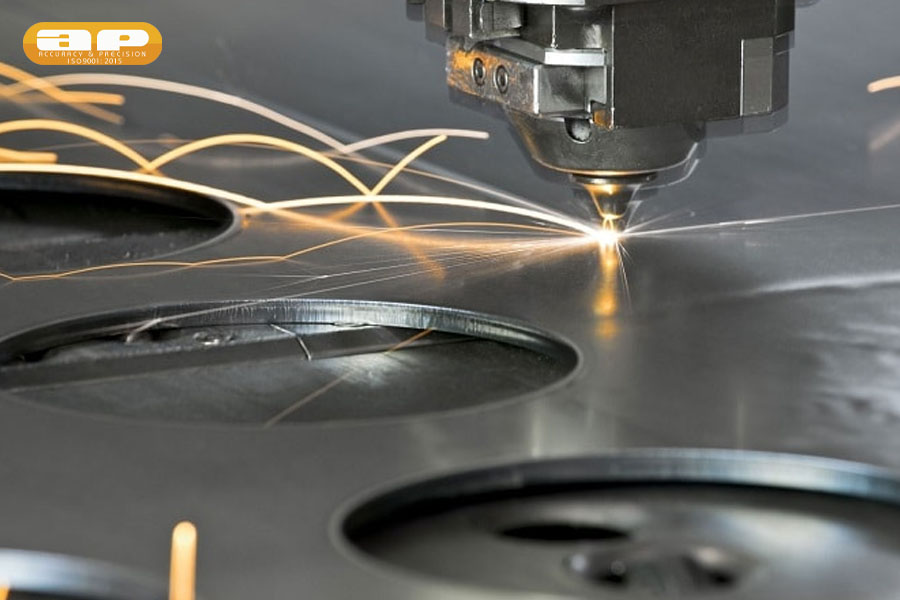

Technology CNC cutting technology is cutting metal according to any curve based on the control of computer software. CNC cutting on demand machines can work in 2D, 3D, etc. Meanwhile, traditional metal cutting machines can only handle cutting lines with certain shapes. CNC machines are easily implemented by specialized software and can work well even in 3D space.

In order for CNC machines to cut accurately, people will design technical drawings. in 2D, 3D and then programmed on the computer to cut according to the desired shape and contour of the product, the CNC machine can cut lines with complex patterns and can cut metal thickness up to 25mm depending on the requirements. into each CNC cutting technology.

At Apro, we apply modern CNC cutting machines to process sheet metal up to 25mm thick. The machine can cut materials such as stainless steel, iron, steel, aluminum, copper, corrugated iron, zinc.

Working principle of CNC cutting machine

When using a CNC cutting machine, it will create very smooth and delicate products. The operation of a CNC machine is not too complicated, the machine is operated on the general principle that the main shaft will move in the Z direction from the top, the table holds the product in the X, Y axis, bringing the cutting edge to all product surfaces. Products.

Before handing over the machine, the staff will guide you carefully from the most basic steps. After a while, you can operate this machine.

Features of CNC cutting on demand machine

Following are some advantages of cutting machine CNC on request, specifically:

- CNC machining on all different materials such as: metal, plastic, copper, non-metal, aluminum, iron, steel, paper,…

- Can cut magnetic materials and non-magnetic.

- CNC cutting on demand technology produces finished products without reprocessing, saving production costs.

- In the normal cutting process, it is easy to deform the product. While using CNC cutting technology, because the heat-resistant area is very small, it will reduce the possibility of metal warping and deformation.

- No noise, good working conditions. Workers will be less exposed to dust and smoke compared to other mechanical processing methods.

- In fact, CNC cutting technology allows to reduce contamination of metal workpieces, providing certain advantages over traditional mechanical cutting techniques.

- Able to work in liquids, solids, air, vacuums, liquids, solids, … so that there are many special applications that no other technology can do.

- Can cut metal in any straight line or curve, cut different thick and thin surfaces, intricate details.

- CNC cutting machine will finish in less time than required by conventional cutting machine.

Some applications of CNC cutting in life

Machining CNC cutting on demand brings many conveniences to life and is applied in many different fields such as:

- In interior and exterior decoration: detailed engraving on tables, chairs, cabinets, drilling and cutting walls. compartments, decorative sculptures,…

- In the field of decoration and advertising: engraving letters, drilling holes on billboards, carving patterns on wood,…

- In decorative wood processing, products art, mica processing,…

Prestigious CNC machining unit on demand

Apro has been highly appreciated by many customers for its professional and prestigious service in recent years. Modern, fast production technology and process, on-time delivery and high quality products as committed.

When coming to Apro, customers will see the professionalism of CNC cutting services on demand, you will be consulted by enthusiastic, dedicated, responsible staff and give you the most optimal solutions.

Commitment to CNC machining services on demand at Apro

- Guaranteed cutting CNC according to customer requirements easily with all different shapes.

- Accurately perform details with high difficulty and complexity such as: V-groove, bent corners,…

- Design customer’s drawings and deliver products in accordance with drawings.

- CNC cutting on demand on iron, steel, stainless steel, … with high hardness.

- Fast machining time saves time.

- A team of highly skilled and experienced technical staff in the field.

- Processing difficult, delicate details that other equipment cannot do.

you need to process CNC cutting on demand with cheap price – quality at Apro, please contact Hotline: +84 774 168 999 for advice and quotation.