CNC milling machining methods in mechanics

CNC milling machining is a very important stage in mechanics, CNC milling is one of the economical machining methods but still produces good quality products. So to understand more about CNC milling machining, follow along in the following article.

What is CNC Milling Machining?

CNC milling machining is a form of manufacturing that removes material from a workpiece to create a finished shape. CNC milling, similar to CNC turning, relies on computer programming to create parts. However, they differ in how they work.

CNC milling in mechanics is extremely necessary because it can be applied in most machining operations with many different requirements, from simple to complex.

CNC milling machining methods in mechanics

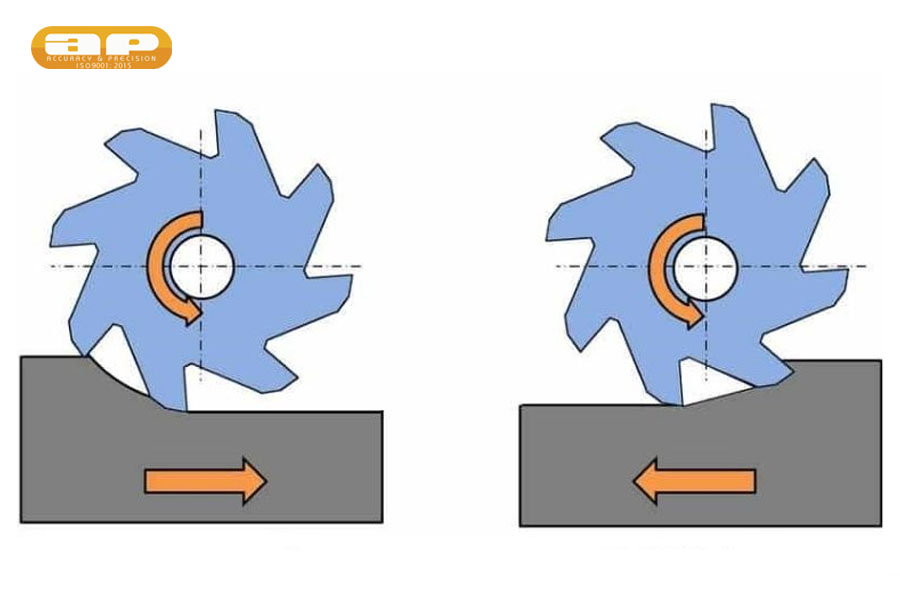

In mechanical CNC milling machining There are two commonly used methods: Forward Milling and Reverse Milling.

Forward

Milling Method Forward milling is a milling method where the direction of rotation of the milling cutter is in the same direction as the reciprocating direction of the table. Forward milling is often applied in finishing because it improves the surface roughness of the part.

Advantages of forward milling

- Helps maintain durability and prolong tool life.

- Less affected by cutting heat because the forward milling process generates relatively little heat and tends to decrease gradually.

- Surface roughness is improved due to gradual reduction in depth of cut, no slippage.

- The cutting force is always on the part, so it is easier to process the jigs, reducing costs.

Disadvantages of forward milling

- Only good processing when the machine has good decontamination, the table must be tightened.

- Difficult to work with hard-shelled workpieces.

- Due to the cutting thickness from thick to thin, there will be a strong collision between the milling cutter and the workpiece surface at first, causing chipping and reducing machine life.

Reverse milling

method Reverse milling method is the method where the tool rotation direction is opposite to direction of reciprocating motion of the table. Reverse milling is applied to rough milling to remove the hard surface layer of the workpiece.

Advantages of reverse

- machines run quieter due to less impact.

- Limit chipping when the part is cut from thick to thin

- Achieve high productivity in roughing.

- Applicable on old milling machines due to the removal of the machine’s dirt.

Disadvantages of back-milling

- It is easy to get stuck between the cutter and the surface, affecting the milling process.

- Large cutting heat because of cutting details from thin to thick.

- Milling blades wear out faster than forward milling.

- The cutting force tends to pull up the workpiece, so a large clamping force is required.

- Slip phenomenon when feed amount is small.

What materials are CNC milling on?

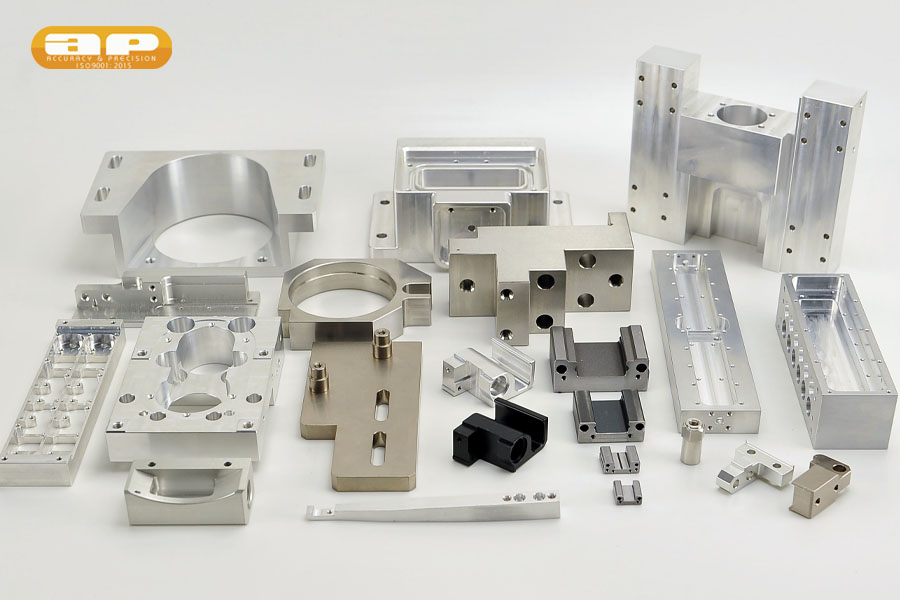

CNC milling machining is used on materials such as iron, copper, steel, titanium, aluminum, cast iron. In addition, the cnc milling machine is used for materials that traditional mechanical machines cannot process such as ABS, Nylon, POM, foam, wood, glass,…

Note some materials do not use CNC milling machines such as: rubber, silicon, ceramic,…

Features of the milling method

The ability of the milling method

CNC milling machining has a high applicability to be machined on many different surfaces with complex parts, a number of applications in machining. milling operations such as:

- Cylindrical

- Milling Thread

- Milling Plane

- Milling Slotting, Keyway

- Milling Profiles

- Milling Key Shaft Milling

Productivity and Accuracy in CNC milling machining

Precision, Surface Quality and Productivity The output when applying CNC milling depends on factors such as:

- The state of the machined surface

- The rigidity of the milling machine system The

- workpiece material

- The material and the quality of the milling cutter.

- Skill of the machinist

Advantages of CNC milling machining

- Accuracy in CNC milling machining is relatively high.

- High applicability, the total volume of machining, milling accounts for about 20%.

- Machining is safer because the chip breaks, causing less danger to the mechanic.

- Because the milling cutter has many blades, it usually takes a long time to wear, and the tool feed is large, so the milling method brings high production capacity.

Disadvantages of CNC milling machining

- CNC milling machining is difficult to apply with thin parts because the workpiece is very fragile during cutting. Normally, metal workpieces must have a thickness of 0.8mm or more to be applied in milling.

- The cost of CNC milling machines is quite high.

Some notes when processing with a CNC milling machine CNC

milling machine is a popular machine on the market today, so there are many CNC milling machines with different origins and prices.

Choosing a quality machine is not an easy thing if you are not an expert in the field. Therefore, you should choose to buy the device in a reputable place with a long-term policy.

The operation of a CNC milling machine is not difficult, but the investor must learn carefully before deciding to use the CNC milling machine processing method.

You can find a professional and reputable CNC milling machine specialist Apro today. Apro has preferential policies for customers and long-term warranty policy when using our services.

For more details about CNC milling machining, please contact Hotline: +84 774 168 999 for service advice.