Receive CNC precision machining on request

CNC precision machining, also known as cnc machining, uses modern machinery and equipment to process products with high precision. Apro unit with many years of experience in CNC precision machining meets all your needs. Learn more about mechanical processing methods below.

What is CNC precision machining?

CNC precision machining is a mechanical processing process that creates high-precision products by using modern machinery and equipment such as cnc milling machines, cnc lathes, and cnc lathes. cnc wire cutting,… with high capacity and the most precise technique.

All CNC precision machining is done through computerized technician controls. CNC precision machining is the use of cnc machines, also known as cnc machining.

Advantages of cnc precision machining

CNC machining has many Many outstanding advantages such as:

- CNC machining machines operate based on coded commands from the control unit, and then give orders to moving equipment such as drilling, grinding, knives, milling, turning, … so CNC precision machining can be performed on different materials, including high hardness materials.

- CNC precision machining ensures high product accuracy such as product surface smoothness, low error, high aesthetics, smooth curves and high drawing scale accuracy. , ensure accurate and stable cutting, the best quality product.

- Increase mechanical processing productivity: the machine works continuously, without interruption.

- Perform CNC precision machining at a high level of complexity: fast machining of small parts.

- Flexibility in processing: one machine can process many materials such as plastic, wood, metal,…

Current CNC precision mechanical processing technology

Currently, there are 3 main technologies applied in the processing industry. mechanical processing in Vietnam:

- Workpiece processing technology: The form of machining is cutting, sharpening, milling, drilling, grinding by machines but still with the support of human hands.

- Non-workpiece mechanical processing: Operations such as casting, forging, pressing, stamping, welding… This machining method is also known by many names such as pressure machining, deformation processing or hot machining.

- Other machining technologies such as ultrasonic machining, electric spark machining…

The most popular precision mechanical machining methods

CNC grinding

uses CNC technology to grind the surface of all kinds of materials. Whether. Especially materials with high hardness such as hard steel, hard alloy.. or brittle materials such as glass, granite. The machine will smooth, abrasive, remove excess substances on the surface, polish the surface beautifully.

CNC Machining

This is the process of thinning the surface, creating a beautiful, smooth surface, bringing it to a thickness suitable for design requirements. Commonly used in furniture manufacturing, machine shell manufacturing, etc.

CNC milling

This is a method of using rotary cutters to cut materials. Metal parts are shaped by multiple blades through two movements: the milling cutter rotates and the cutter moves in three directions.

CNC milling machines can cut many materials such as iron, steel, stainless steel, aluminum, titanium, etc. Machining complex planes, curved surfaces and shell parts such as drives, dies, connecting rods, cutting blades, etc. machine case, machine components…

CNC drilling

This is the machining process using a drill blade. For drilling holes in metal surfaces, materials. The drill has high accuracy, continuous performance and reduces construction time. Drills have different depths according to pre-designed programs.

CNC drilling technology with high precision is used to create holes in the surface of the product block in accordance with the production requirements.

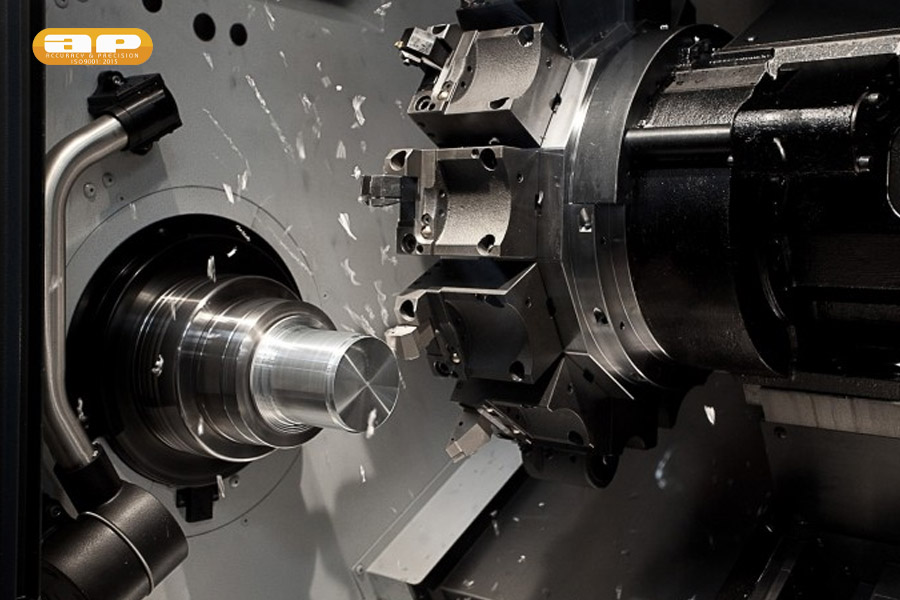

CNC Turning Machining

Similar to cnc milling machines, but cnc lathes are used to create cylindrical products. The product rotates and the cutting tool makes a slight cut into the product, removing excess material and shaping the product.

CNC lathes are used to process some complex rotating surfaces such as hyperboloid or linear cylinders, inclined cylinders and various threads. Create a variety of products from simple to complex such as machine parts, shapes, cutting gears, chamfers, corners, etc.

CNC gear cutting machining

Using CNC waterjet cutting machine combined with milling, tooth slotting, shaping, … to create mechanical gears, ensuring rigidity and exactly as the drawing.

Apply this method in all production activities of machine gears, vehicles, gears, racks in mechanical machines.

CNC

sawing CNC sawing machine is used to cut out curved parts according to CNC programming on drawings with fast speed and high accuracy. Application to cut details according to drawings, cut excess details, create curves for materials.

CNC Broaching

This is the process of enlarging an existing hole in a material using a cylindrical or tapered broach. The broaching knife is made of high-speed steel, Fe-Co alloy, Carbides (hard alloy) that can be cut to exact size, not used for processing and cutting with large residuals.

Drilling through holes with straight centerline and constant cross-section. If the hole needs high concentricity and precise tolerance, then center drilling or spot drilling is required first, then normal drilling, rough reaming, and finally broaching to complete.

Application for processing round holes, all kinds of shaped holes, keys, keyholes or spiral grooves, planes, outer cylinders.

Quotation for cnc precision machining

services Precision mechanical machining services use one or more methods at the same time. Depending on the type of processing, level, quantity, type of material, complexity of the part, the price varies.

Contact for quotation: +84 774 168 999

Materials that are commonly machined by precision cnc mechanics

There are many materials that are machined in mechanics such as alloys, metals, wood and plastics. Specifically:

- Alloy materials: stainless steel, steel, cast iron, alloys of aluminum, alloys of copper

- Metal materials: common metals such as iron, aluminum and non-ferrous metals such as copper, aluminum, lead, zinc, tin, …

- Wood materials: all kinds of wood materials can be processed by CNC machines because of their light, solid and good bearing properties. The finished product is beautiful, the cut is smooth.

- Plastic materials: samples of plastic materials such as Composite (including Grain-reinforced Composite, Fiber-reinforced Composite) can be accurately processed to form marine hulls, machine parts, turbines, etc.

CNC precision machining process

To perform precision cnc machining of humans Engineers need to follow a 9-step process as follows to ensure product quality:

- Step 1: Check design data: Check the exact size, shape, gloss and type of workpiece material. .

- Step 2: Set up the CAM program: Set up the standard NC driver for CNC machining.

- Step 3: Check the CAM program: Manually check by eye or check by computer to detect errors, thereby modifying the program or cutter, cutting mode, etc.

- Step 4: Check Detail machining dimensions: Ensure tolerances to the lowest number.

- Step 5: Determine 2D and 3D standards: If a problem is detected, it must respond quickly to correct it.

- Step 6: Check, check details: Determining the type of knife, the order of the knife and installing the tool is done according to the standard procedure.

- Step 7: Check the workpiece against the drawing and check the material: If the material requires heat treatment, send it to heat treatment and receive it back when the size of the heat treated workpiece meets the requirements

- Step 8: Finish CNC machining: Create Detailed picture is completed according to the drawing given

- Step 9: Evaluate and check the standard size: Check the finished product size to see if it is in accordance with the set standards.

Why choose Apro for precision mechanical processing?

- Competitive cost

- Modern machining system can perform on different thickness workpieces

- CNC machining on all other materials such as iron, stainless steel, plastic, aluminum, copper…

Apro provides cutting services. , CNC precision mechanical processing with a full range of the most modern machines brings automation accurately and quickly.

Apro is the leading unit in precision cnc machining nationwide. The company has many years of experience in the field of mechanical processing through the application of modern technologies combined with a series of good engineers of the company.

you want to consult CNC precision machining at Apro, please contact Hotline: +84 774 168 999 for more detailed information as well as a detailed quote about the service.