Types of Jig molds – popular test jigs

The concept of Jig mold and test jig is still very limited to people, especially those who are new to learning about precision mechanics. In this article, we will introduce to you the exact concept of test jigs, installation processes and popular types of jigs and jigs today.

The concept of Jig mold, test

jig Mold, jig mold is also known as a map jig, used to attach parts or assemblies. These are very necessary and auxiliary items for fixing to assembling, processing workpieces and checking the quality of products. In addition, the test jig has the effect of determining the necessary position of the workpieces, which holds the workpiece tightly during the cutting process to ensure high accuracy.

Uses of test jig, Jig mold:

- It has the effect of fixing the workpiece when processing: Helps to fix the workpiece when processing, this keeps the workpiece from moving and keeps a safe distance between the workpieces. each other at a safe distance.

- Helps to quickly and accurately determine the position and size of the parts faster than the cutter, helping to improve the quality of the product.

- Helps to orient machining on workpieces such as: cutting, drilling, grinding, chiseling, chiseling, …

- Helps improve the production capacity of enterprises, creating complex movements and relative details. difficult.

- From the benefits that the test mold brings, it will accelerate the process of industrialization, modernization and mechanization. It is for this reason that it reduces labor costs and reduces production time for businesses, but the products are still quality.

Structure of test jig, modern

jig mold Test jig, jig mold has diverse designs to suit each type of workpiece and different uses. In general, most types of test jigs are composed of parts such as:

- The part that holds the function of clamping the product

- The part that helps to locate the components of the machined product

- The part with the power transmission mechanism of the machine. products

- Parts with rotating and grading mechanisms products

- Jig mold, test jig with guiding mechanisms

- Including the body and base of the test jig, Jig mold.

- The test jigs, Jig molds have clamping mechanisms.

- The jig mold, Jig mold cannot lack the positioning mechanism.

The most effective types of test jigs, Jig molds

Depending on the suitability of the workpiece products We have the following types of test jigs as follows:

Alkaline jig, Welding Jig jig Welding

jig Welding jig is a processing equipment for welding parts that have relatively complex structures and shapes. The large brace has the effect of keeping the welding fixture stable in the face of pressure and heat.

Mold Jig Assembly

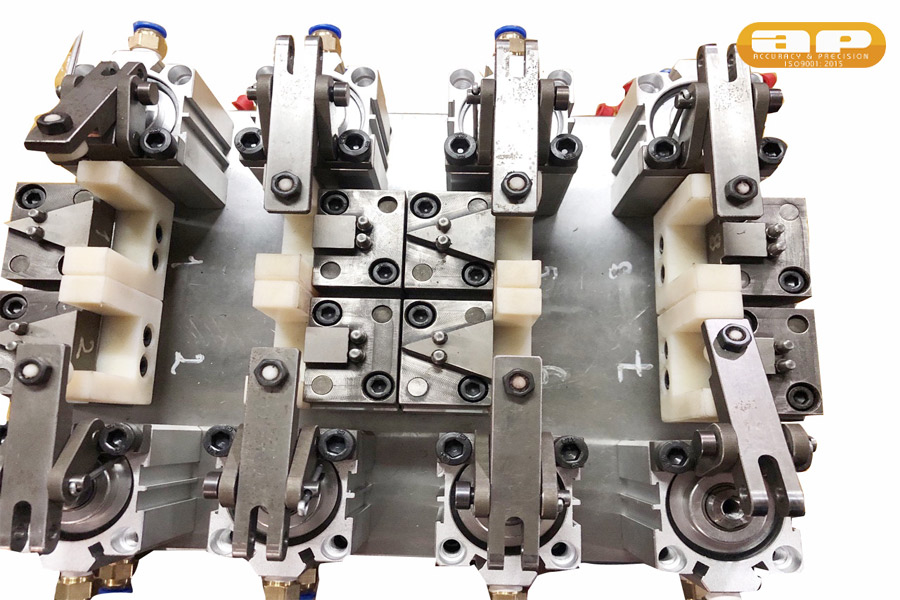

Jigsaw Assembly jigs are used when it is necessary to assemble parts or assemblies with relatively complex structures together.

The assembly jigs appear in many stages such as: during the assembly process to help clamp the workpiece, make the jigs, hold the assembled parts, weld, press the product,…

Jig Jig jig test jig

MoldThis is used when it is necessary to check the specifications. The test jig helps to keep the products fixed, not moved by external forces, helping the products to be manufactured in accordance with customer requirements.

Jig mold Compression jig

This mold is used when it is necessary to fix the details materials before welding or assembling, helping to stabilize the part so that the machining process is safer, more convenient, and faster.

Mold Jig Milling

jigs Milling jigs play the role of locating material parts to carry out the machining process on CNC milling machines. Currently, on the market, there are various types of milling jigs such as: single-piece, multi-piece, round infeed milling jigs,…

Jig molds, roughness

gauges Roughness gauges are used to check the roughness. roughing products in a quick time, quickly detecting non-standard surfaces for re-machining.

Standard evaluation of test jig, jig mold

The evaluation criteria of test jig, jig mold

- are as follows: Good product positioning: when determining the exact position of the details, the machining process is convenient. Convenient, error-free.

- The ability to hold the workpiece firmly: When ensuring that the workpieces do not move, contribute to improving product quality.

- Capable of optimizing economy: One test jig, Jig mold can be used to process many different types of materials, due to the good material, it can be used for a long time and at low cost. change, repair.

- The ability to optimize materials: When manufacturing, it is necessary to choose materials that ensure mechanical properties, helping the mold not to stretch or change shape during use.

How to make test jig, jig mold

Design jig, jig mold for machining. The production of test jigs requires professionalism.

To design and manufacture test jig requires highly skilled and experienced engineers to produce a quality test jig product.

With many years of experience in the precision engineering industry, APRO Precision Machining Co., Ltd. always provides a service package of manufacturing test molds according to the requirements of customers. With a team of dedicated and highly skilled designers, we are always committed to bringing the best quality products at the most reasonable prices. When customers cooperate with our company, with a large number of products, the price will be reduced.

For all consulting, design and product needs, please contact us via hotline 0774168999 for our consulting team to answer.