Methods hardness testing in mechanics

In the mechanical engineering industry, it is often necessary to perform an important step, which is hardness testing to determine the characteristics of the material, before the product is put into use. So what is hardness testing? What hardness testing methods? What should be kept in mind when performing the hardness test? Let’s find out together with Apro below the following article.

What is hardness testing?

In mechanical engineering, hardness test is extremely important in quality control and R&D work. Hardness testing allows you to evaluate material properties such as strength, ductility, wear resistance. Thus, helping you determine if the material or material treatment is fit for the required purpose.

Choose the best method of hardness testing in mechanics

Hardness testing which you choose must be determined by the microstructure. Examples include the homogeneity of the material under test, as well as the type of material, the size of the part and its condition.

When you choose a method due to hardness, you should keep the following factors in mind:

- Approximate hardness of the material

- Is attachment necessary

- Part size

- Number of samples to be tested

- Type of material to be tested hardness test

- Required accuracy of results

- Whether compliance with a standard is required

- Consistency or heterogeneity of materials

Existing mechanical hardness testing methods

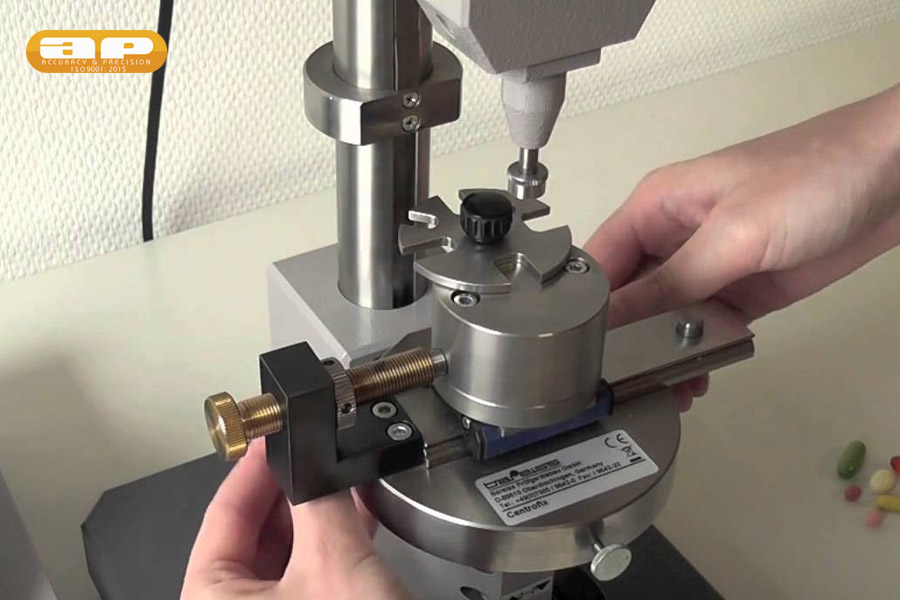

Hardness testing methods Vickers

Vickers is a hardness test for all solid materials, including metallic materials. Vickers hardness (HV) is calculated by measuring the diagonal length of an indentation in the sample material. Left by introducing a diamond pyramidal indent with a certain load. Diagonals of indentations are optically measured to determine hardness, using tables or formulas.

- Suitable for a wide range of applications

- Hardness testing of all solid materials, including metals

- Includes a subgroup of weld hardness test

Rockwell

Hardness test a rapid hardness testing method developed for production control is the Rockwell method, with a method of hardness. Direct reading, mainly used for metal materials. The Rockwell hardness (HR) is calculated by measuring the depth of the indentation after the indent is pressed into the sample material at a certain load.

- A “quick test” mainly used for metal materials

- Usually used for larger sample shapes

- Can be used for advanced tests such as the Jominy test (end of quenching) (HRC)

Brinell hardness

Test Brinell hardness test is used to test the hardness. harden materials with a coarse or heterogeneous grain structure. The indentation of the Brinell hardness test (HBW) leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.

- Used for larger samples

- Used for heterogeneous or coarse-grained materials

- Suitable for casting and forging where structural elements are large

The Knoop hardness testing method

The Knoop is one of the alternatives to the Vickers test in the scope of micro hardness test tissue. It is mainly used to overcome cracking in brittle materials. As well as to facilitate the hardness testing of thin layers. The indent is an asymmetrical pyramidal diamond, and the indentation is measured optically in a long diagonal.

- Suitable for small stretched areas, such as coatings

- Used for brittle and hard materials such as ceramics

Several factors affect the hardness test

Several factors affect the hardness test results. As a general rule, the lower the load you use in the hardness test, the more factors that need to be controlled to ensure an accurate conclusion of the hardness testing.

Here are some of the most important factors to consider to ensure accurate conclusions from hardness testing:

- External factors such as light, dirt, vibration, temperature and humidity should be controlled

- The test and stage shall be fixed on a stable horizontal table and the specimen shall be clamped or held in a support or anvil.

- The indent must be perpendicular to the surface to be tested

- Brightness setting must remain constant during testing when using Vickers, Knoop or Brinell

- The tester must be recalibrated/verified each time you change lenses or objects Glass

Above are some sharing about guiding common hardness testing methods. If you have any questions, please contact us via Hotline: +84 774 168 999 for advice and support.