Step-by-step instructions for 4-axis CNC programming

Currently, the use of software and computer technology to perform 4-axis CNC programming is not too strange and it has become much more popular. If readers are looking for 4-axis CNC programming , please read this article immediately to get more information about 4-axis CNC programming.

Learn 4-axis CNC machining and 4-axis CNC machining

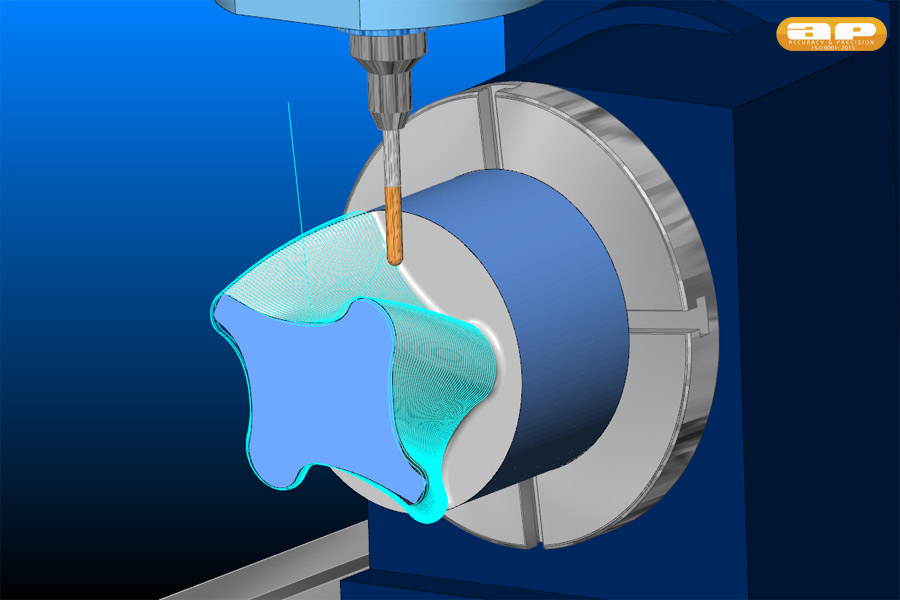

For a business with high precision mechanical processing, they will often use 4-axis or 5-axis machining machines. 4-axis machining machines are capable of processing much more detail than 3-axis machines, and the running lines are also more sophisticated.

4-axis CNC machining machine operates vertically, operating very flexibly, Suitable for processing highly complex parts.

Learn about CNC programming 4X B axis Machining

programming is not a complicated job, but it needs high precision, the operations need to be done carefully.

4X B-axis CNC programming will apply to 4-axis CNC programming, the 4th axis will rotate around the Y-axis, called the B-axis.

4X B-axis CNC machining programming makes machining complex parts become more difficult. should be easier than ever.

Conditions for 4-axis CNC programming software to work

- The software needs to have many options to avoid errors during use and options

- Must have a microprocessor that can handle all rotations

- Have a control management function control, accurately calculate rotations

- The software inside the software must be full of automatic functions

Guide to 4-axis CNC programming steps on the software

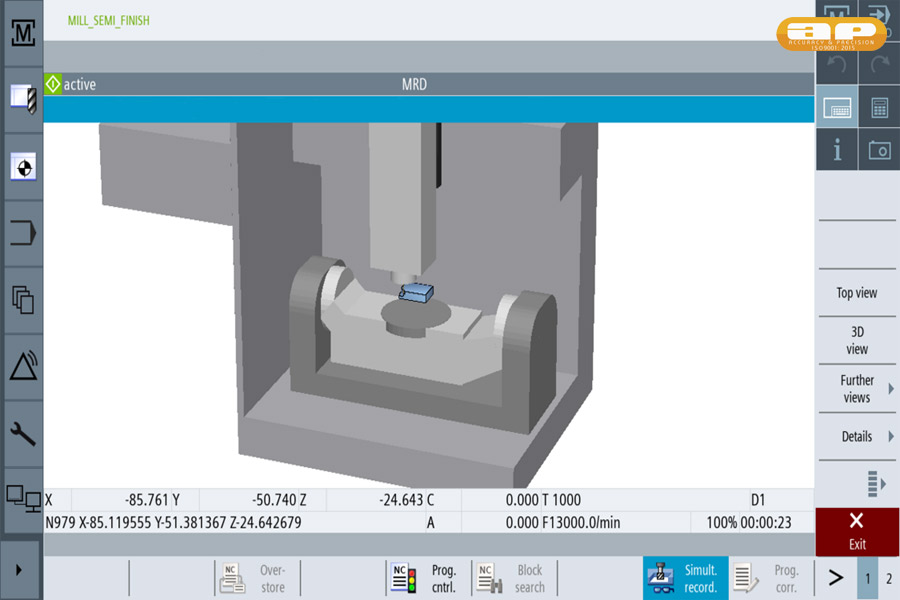

Currently there are many softwares to help perform CNC programming 4 shaft easier and more precise. Below are the steps to perform CNC machining programming on popular software today.

Setting up the environment in 4-axis CNC programming

Step 1: Open the work piece.

- Select File on the toolbar

- Select Open, open File

Step 2: Set up GC.

- Select Tool

- Select the software, add New, select Milling

- Select External

- Select Yes

Proceed to use using jigs in 4-axis CNC programming

- Open Insert components

- Select Browse

Perform machining programming in 4-axis CNC programming

- Use 2D or 3D features

- At this step it is necessary to set the origin 4X or B

- Check with simulations

Should when to use 4-axis CNC machining machine?

When you need the highest quality product, when dealing with difficult parts, often used in medical devices.

Normally on a 3-axis CNC milling machine, the milling slots, drill holes, and cutters are all in the vertical direction, now in addition to the X axis, more flexible hole details can be created.

When using a 4-axis CNC machine, it takes less time to process details than a 3-axis machine. The machine is also easier to use for the operator.

CNC machining

fields Many different fields need to use machines 4 Axis CNC machining such as:

- Industry

- Technology Research Industries Art

- Creation

- Industry Medical Device Industry

Cost of 4-Axis CNC Machining Machines

Overall. The cost to process a 4-axis CNC machine will be higher than that of a 3-axis CNC machine even with just one more turntable. However, because the size of the turntable will affect the cost of the CNC machine.

If you want to ensure accuracy, or process products that require accuracy and save time and improve productivity, then 4-axis CNC machining is a great choice.

Thus, we have introduced to you the information about 4-axis CNC machining, to program 4-axis CNC and the steps to implement them. Hopefully from the information we provide, readers as well as customers have the right choice.