What is precision mechanical manufacturing? Classification and advantages

The mechanical industry is playing an important role in economic development. Precision mechanical manufacturing is a field that requires meticulousness and high precision in the detailing process. Precision mechanical manufacturing creates a lot of products that meet the needs of people in life. Let’s find out more details about the precision mechanical manufacturing industry with Apro below the following article.

What is precision mechanical manufacturing?

Precision engineering is a term used exclusively for mechanical engineering. Humans will use modern machines and technology to create products with almost absolute accuracy. All products created from the precision engineering industry are applied to people’s lives.

Precision mechanical production requires meticulousness and precision high in the processing of parts. Core areas include mechanics, dynamics, thermodynamics, materials science, structural analysis, and madness. Engineers use these core principles along with tools like computer-aided design and product lifecycle for design and analysis.

Precision mechanical processing is a machining activity that uses modern systems and machines such as grinding machines, drilling presses, milling machines, lathes, etc., together with high-speed, high-capacity robots and techniques. accurate to work. Precision mechanical industry applies to different types of materials such as glass, steel, stainless steel, coal, lead, plastic,…

Classification of some common precision

mechanical manufacturing industries Main mechanical manufacturing industry based on many different factors and characteristics. The following are some common classifications as follows:

- Precise mechanical manufacturing technology without workpiece: This is a form of deformation processing, using pressure, also known as hot machining. Machining forms appear quite popular such as casting, hot stamping, welding, drawing, rolling, pressing, …

- Precision mechanical processing technology by workpiece: includes cutting, sharpening, grinding, drilling operations,milling, planing,…

- Some other precision mechanical processing industries: including machining methods such as spark machining, ultrasonic machining, cnc machining, cnc turning, cnc milling, laser processing,…

Advantages of the precision cnc mechanical processing industry

When using the precision mechanical processing method, you will receive the following advantages:

- The precision cnc machining machines are capable of doing The work is automatic and continuous so it helps to reduce the production time.

- This method does not require operator skill. No worker effort, but the processing productivity is still high, thereby reducing labor costs.

- Programs can be used many times.

- CNC precision machining machines produce high-quality products with few errors, so there is no need for labor and re-testing time.

- The machine is capable of continuous operation with little downtime, thereby increasing the working time of the machine.

- Easy and flexible in processing rotation from one product to another.

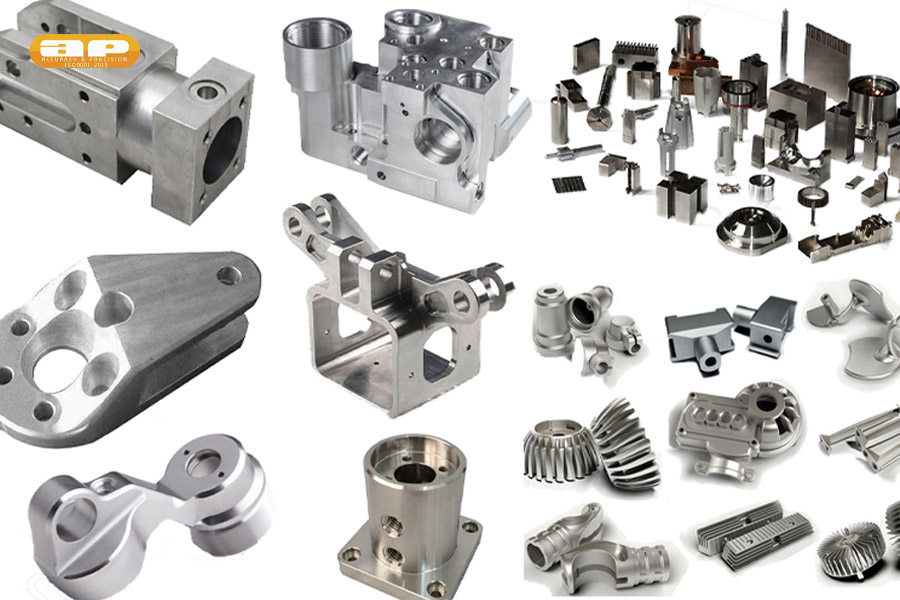

Some products in the precision mechanical manufacturing industry

Products created from the precision mechanical manufacturing industry, we can easily encounter items in daily life. All kinds of simple items or highly complex items can be done.

Products of the precision mechanical manufacturing industry appear in our lives and families such as: exterior decoration items, furniture, kitchenware, household appliances. Products that are considered simple production are not too sophisticated.

Some complex products require high level of accuracy and precision such as products in the medical industry, automobile industry, military, aviation, etc. These are machine parts used in assembling umbrellas. cars, airplanes or medical devices, etc. There are other products that we can mention.

The concept of CNC in precision mechanical

machining CNC stands for the phrase Computer Numerical Control in English, which is a term that refers to lathe systems, mechanical engraving machines controlled by computers.

A technology that was developed in the late 1940s – early 1950s in the MIT Servomechanism Laboratory.

Operated by computer control, CNC machines can easily cut and trim metal whether curved or straight, even hollow inside the workpiece, trimming precise patterns.

Because it is programmed and controlled by a computer, the accuracy of CNC is said to be absolute compared to the design, the products processed by CNC machines have very sharp cutting lines and high aesthetics. .

Some common materials in precision mechanical manufacturing

The following are some materials in precision machining:

- Iron: This is a metal extracted from ore mines, iron is used in the production of iron and steel. , the demand for precision machining of iron accounts for about 95% of the volume of metal produced in the world.

- Steel: This is an alloy of iron and carbon and add some other elements, steel has 2 types: carbon steel and alloy steel.

- Cast iron: An alloy of iron and carbon, people often use cast iron for mechanical processing as required for machine parts with different complex shapes.

- Stainless steel: Known as stainless steel, the alloy form of iron in which there is 10.05% chromium. Stainless steel is often discolored and corroded like ordinary steel. Stainless steel is widely used in our daily life.

Types of cutting tools used in precision mechanical processing:

Tools used in precision mechanical processing are tools with higher hardness than the part to be processed, installed in machine tools (lathes, milling machines, planers, drills, ..) to serve the industry. precision mechanical processing, for the purpose of manufacturing mechanical parts, serving the assembly, manufacturing or repair of machines and equipment

Mechanical cutting tools are very diverse, such as: knives lathes, milling cutters, planers, drill bits, reamers, taps, saw blades and specialized tools.

Metal cutting tool

material The metal cutting tool material must have a higher hardness than the work piece, and the tool must be able to withstand the heat generated during metal cutting.

There are many types of materials for cutting tools, but depending on the processing material and the processing mode, people choose the tool material for precision mechanical processing to be reasonable and economical. To choose a material for a metal cutting tool, one considers the following requirements:

- Hardness: is the ability not to deform when used to cut the workpiece.

- Thermal strength: The ability to retain hardness and mechanical strength at elevated temperatures.

- Mechanical strength: Ability to withstand force during cutting.

- Wear resistance: Resistance to abrasion during cutting.

Apro is a unit specializing in processing products from precision mechanical manufacturing. Here you can clearly understand what precision mechanical manufacturing is and the advantages of this method. If you have a need for precision mechanical processing, please contact us immediately via Hotline:+84 774 168 999