Description

Apro Engineering, we produce precision tubes following requirements.

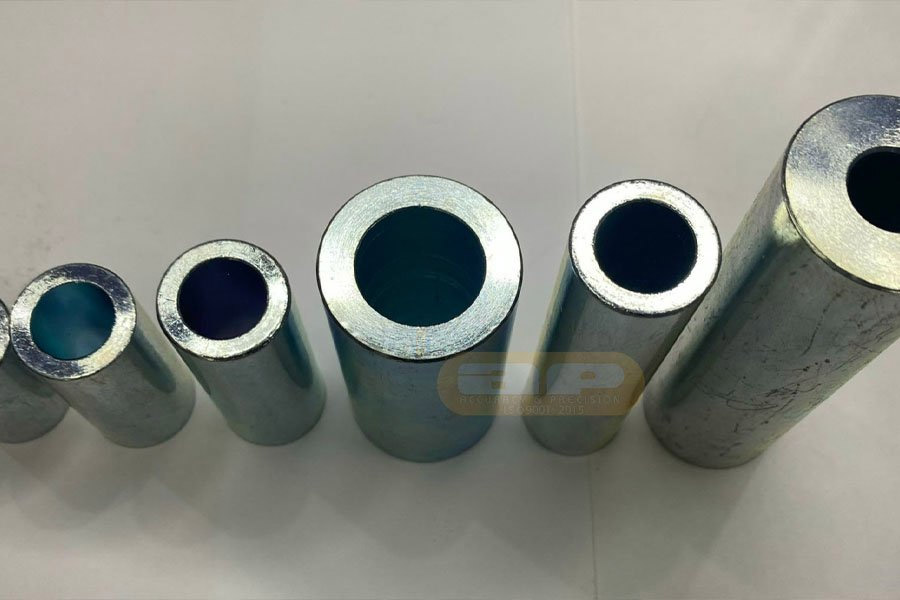

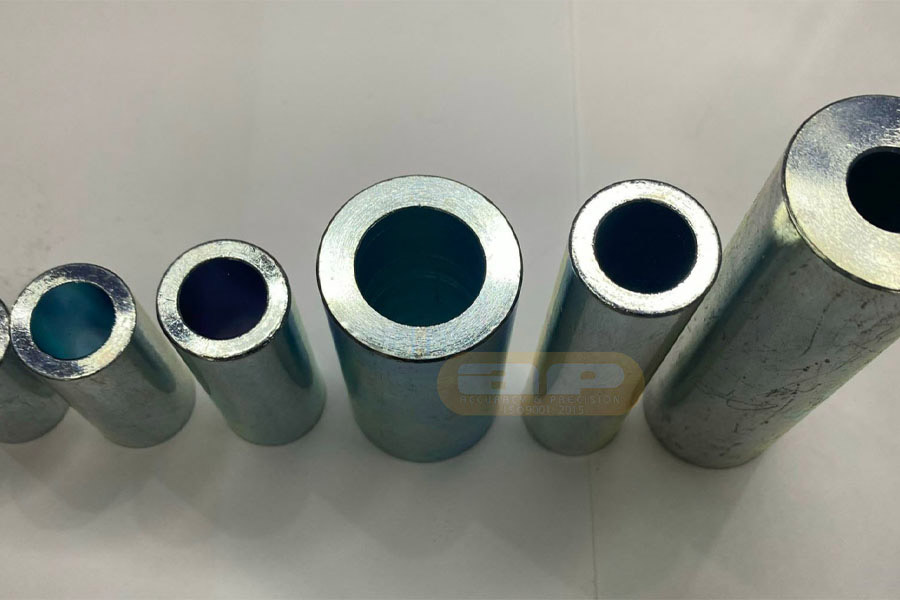

Machining process

1. Precision tubes is imported a correct inner diameter and an outer diameter or machined correct ID and OD by CNC lathe.

2. Requested lengths are cut by automatic saw machines or by CNC lathe following high tolerance

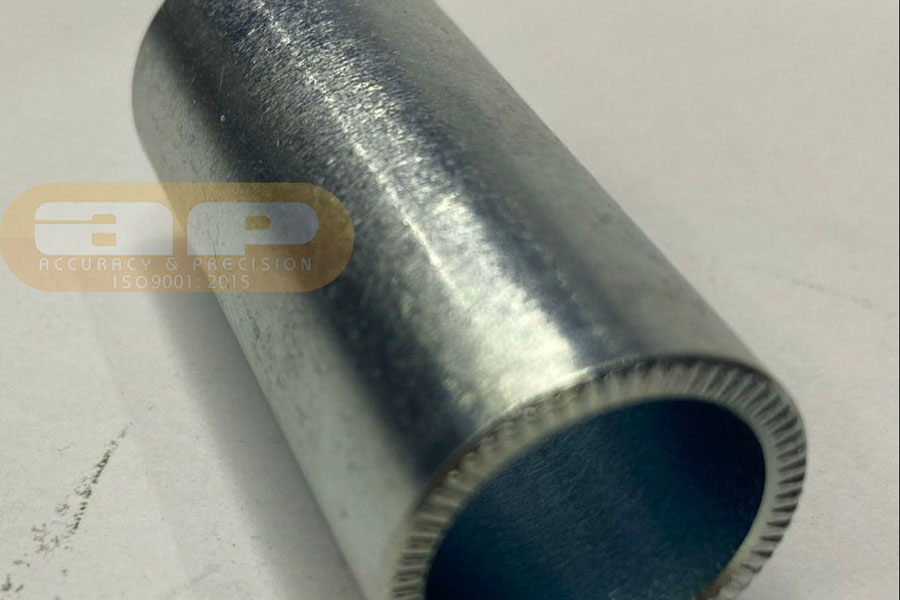

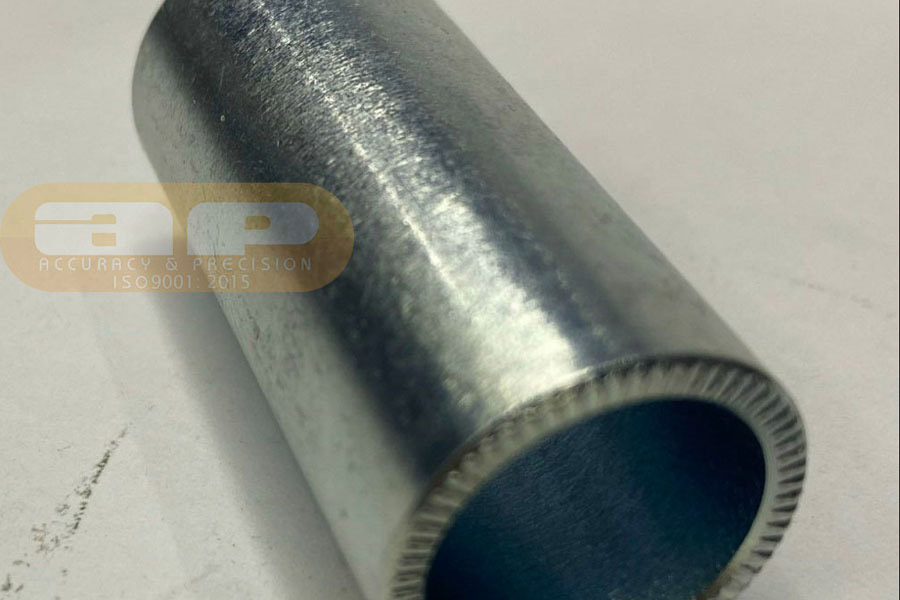

3. Chamfer locations of ID and OD by an automatic chamfer machine (high volume) or by CNC lathe

4. Heat treatment as requested

5. Hardness testing by a hardness testing machine

6. Plating Cr3+ or anodizing as requested

7. Salt spray testing following ASTM B117 or ISD 9227 standard

8. Finished products measuring

9. International packaging standard

Standard of products

1. Certificate of precision tubes

2. Diversity of diameter as requested

3. Supply carbon steel AISI 1010 ~ 1045, S20C ~ S45C, stainless steel SUS304, SUS304L, SUS316 and SUS316L, aluminum 6061 ~ 7075

4. Physical and chemical analysis testing by the third party as requested

5. Finished products checking report

6. High tolerance as 0.002mm

The process instructed

Precision tubes products are used diversity of processes such as automotive industry (OEM and aftermarket), textile industry, food packaging industry, pharmacy industry and aircrafts industry …